Automated Fill Finish System Item Code: 3370786

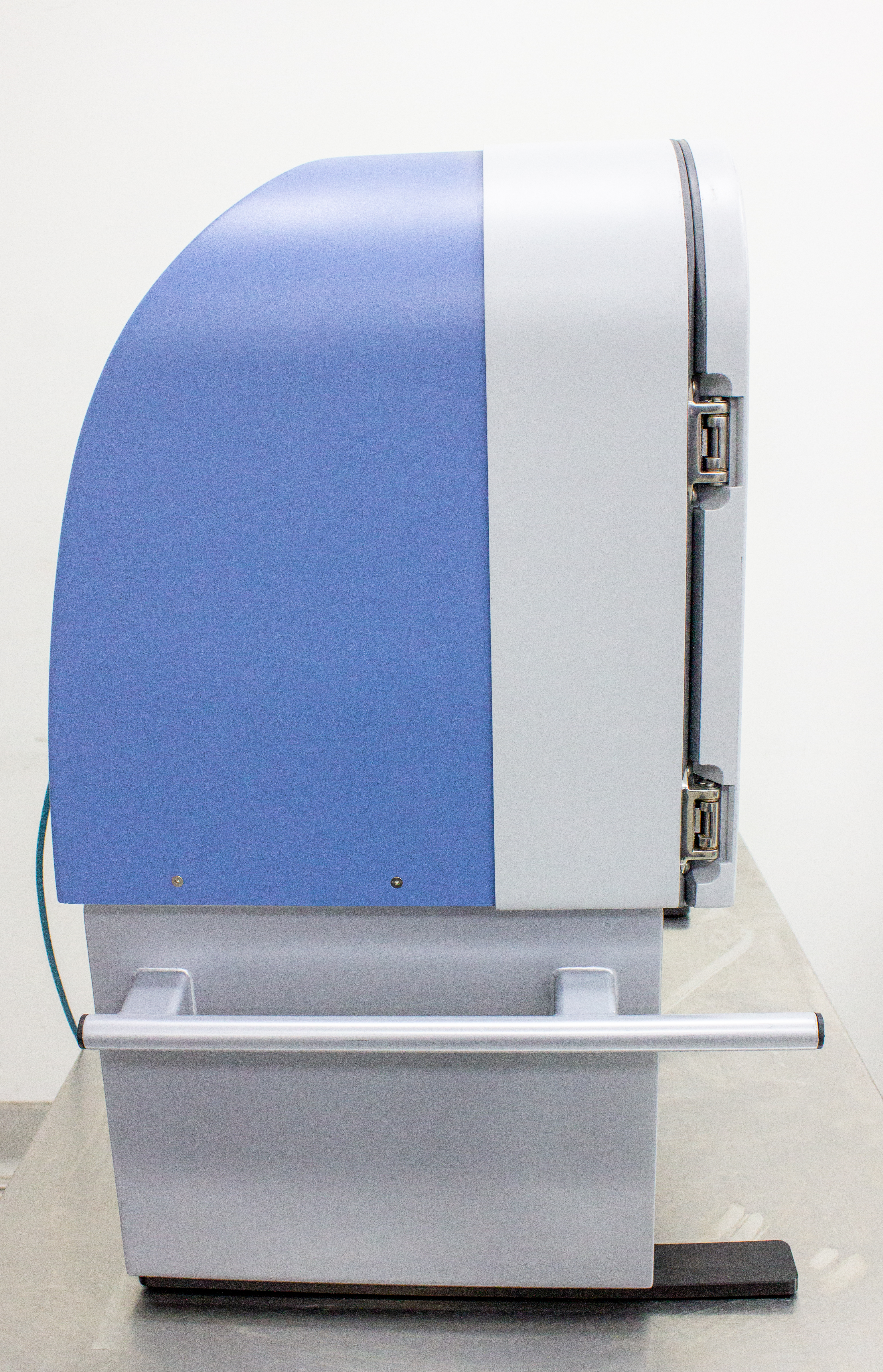

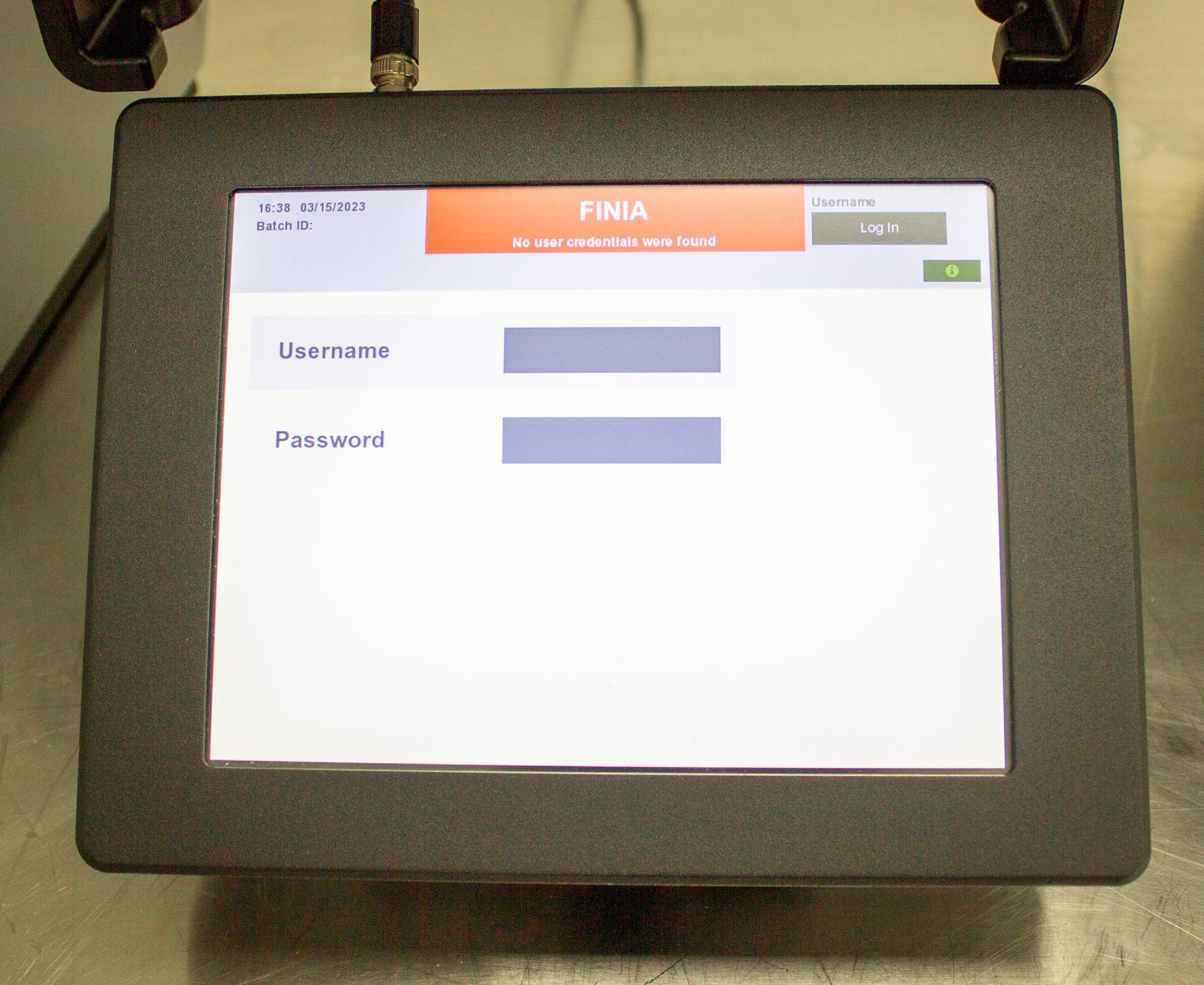

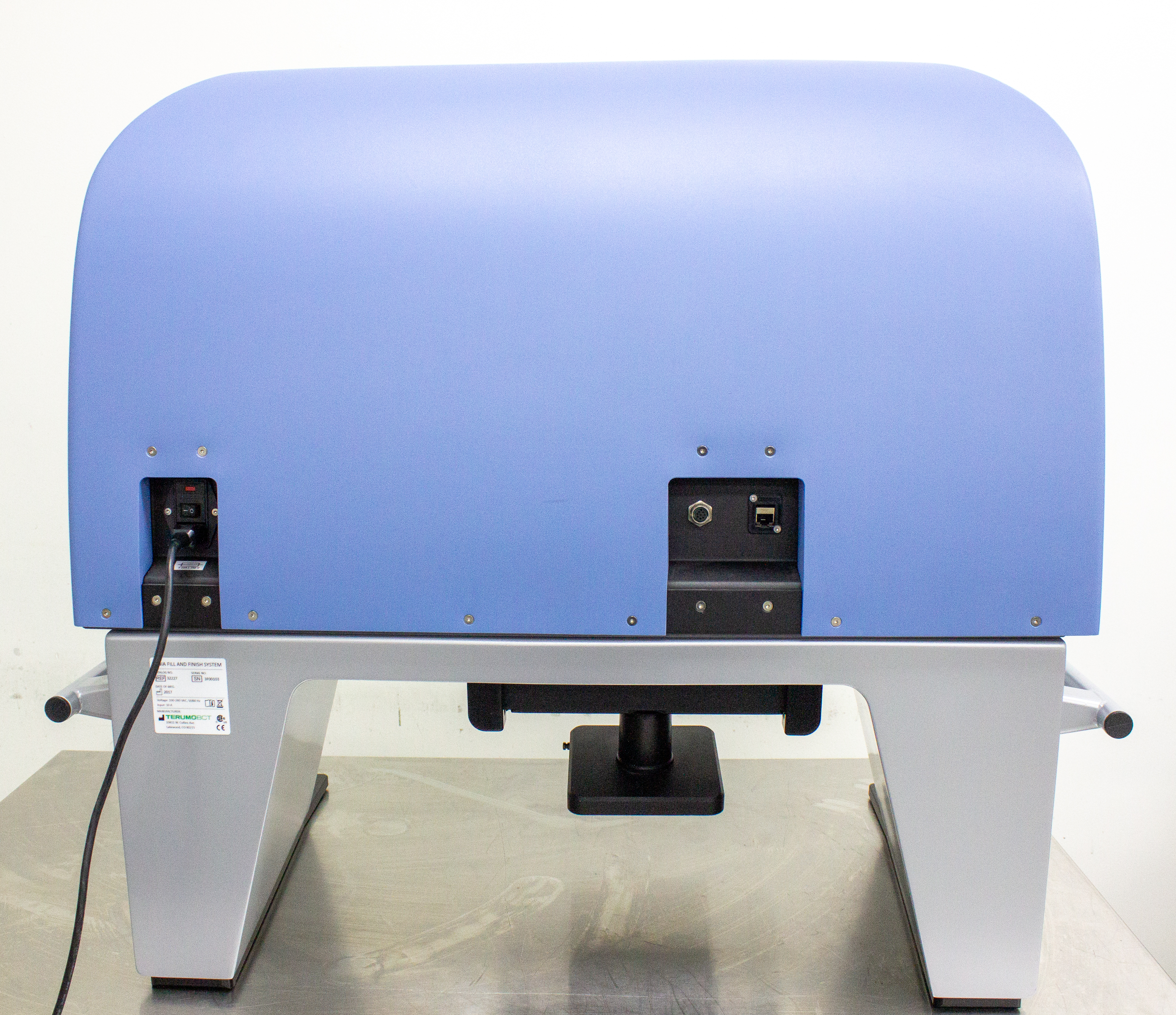

The Terumo Finia Fill and Finish System, manufactured in 2017, is an innovative automated solution for cell and gene therapy developers looking to eliminate manual processes and achieve precise, consistent results. While the unit powers on and includes a monitor, full access requires a password. The system automates the formulation and aliquoting of fluids, including cell suspensions, for cryopreservation. Ensure over 90% viability for cell products from T-cell donors and maintain cell concentration uniformity within 5%. The compact benchtop design incorporates mixing, cooling, air removal, aliquoting, and sealing processes, supporting cGMP compliance with electronic data management. Suitable for laboratory and industrial settings, the Finia system offers significant time savings with only 12 minutes required per run.

Key Features

- Automated formulation and aliquoting

- Supports cell therapy and gene therapy

- Ensures >90% post-thaw viability

- Maintains cell concentration uniformity to 5%

- cGMP compliant electronic data management

- Compact benchtop design

Specifications

- Volume accuracy: within 2 mL of target

- Product volume range: 20 mL to 174 mL

- Gamma-sterilized, functionally closed tubing set

- Device weight: 147.5 lb

- Environmental specs: <44,000 particles >0.5 microns/m3

- Electrical: 100-240 V AC, 50/60 Hz

- Safety certifications: IEC 61010-1, EN 61326-1

Weight

Imperial: 177.6 Pounds

Metric: 80.56 Kilograms

Shipping Dimensions

Imperial: 24.0 lb x 42.0 lb x 44.4 lb

Metric: 60.96 cm x 106.68 cm x 112.78 cm

Harmonized Code

9031.80

Harmonized Code Details

9031.80 - Measuring or checking instruments, appliances and machines, not specified elsewhere. Suitable due to its usage in precision measurement and control during cell processing.